Portal for more climate-friendly mobility

In brief

Interesting facts and news from the world of climate-friendly mobility – at a glance.

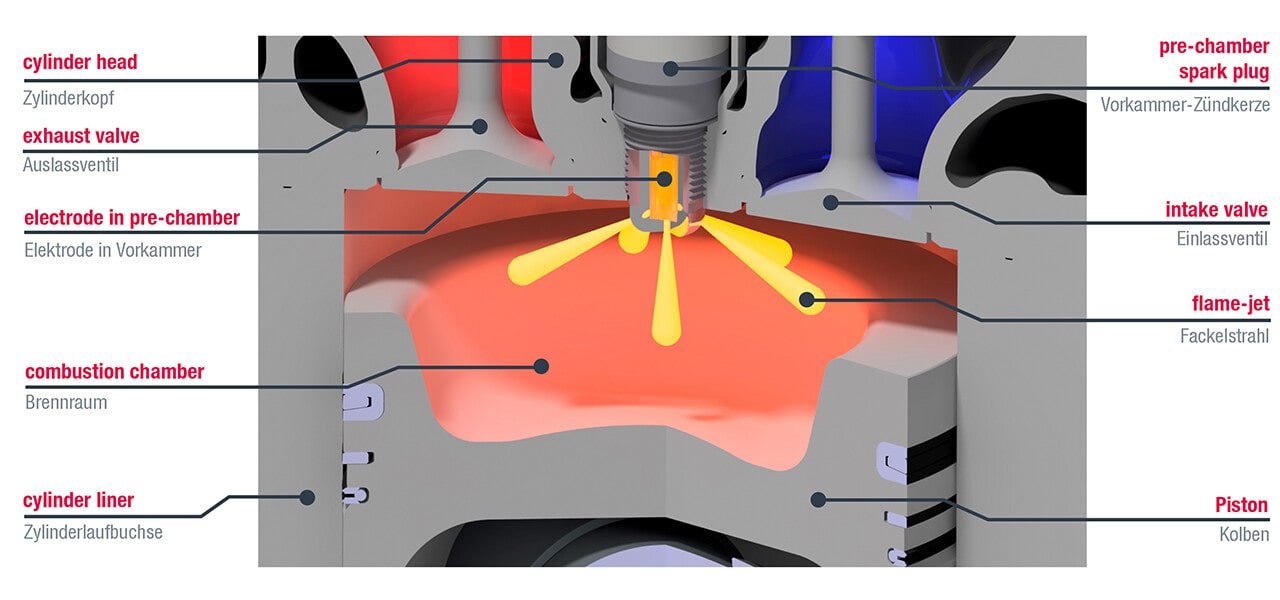

MAN Engines with a brilliant idea

Efficiency increase for turbocharged CNG engines

MAN Engines is now offering all turbocharged CNG engines of the current MAN E3262, E3268, E0836 and E0834 series as an option, and MAN E3872 as a mandatory option, with prechamber spark plugs adapted to the respective combustion chamber. Due to the backwards compatibility, existing combined heat and power plants (CHP) with the twelve-, eight-, six- and four-cylinder engines mentioned can also be retrofitted with prechamber spark plugs using the lean-burn method. This includes operation with hydrogen-containing fuels with up to 20 percent hydrogen admixture by volume. A modification of the engines is not necessary for the use of prechamber spark plugs. Due to the software adjustment of the ignition timing and the reduction of the energy demand, less powerful ignition control units may be required. Especially in low-NOx applications, the prechamber spark plug offers some distinct advantages over the conventional spark plug. A clear advantage of prechamber spark plugs is their longer service life, which is influenced among other things by the lower ignition energy. In addition, MAN engines with prechamber spark plugs offer better combustion quality. Another advantage of prechamber spark plugs is also their greater flexibility in terms of ignition conditions. “As added value, we offer our customers higher efficiency and lower maintenance,” explains Reiner Roessner, Head of Sales MAN Engines.

Citywide buses powered by CNG

Biogas for sustainable urban transport

Following an initial delivery of five 18-metre Citywide CNG buses from Scania in 2020, the western French city of Angers Loire Métropole has now taken delivery of further vehicles miT CNG propulsion, complimenting its biogas vehicle fleet of 15 CNG vehicles in total. “The choice of Scania was based on a technical and financial analysis. The reliability of the Scania engine and the quality of the technical documentation are particularly appreciated by the workshop,” explains Noël Vignol, who is responsible for the maintenance of the buses at RATP Développement Angers. The CNG buses are equipped with a 320 hp 9-litre CNG engine and an automatic transmission from ZF Ecolife. “Our depot in Saint-Barthélemy-d’Anjou has been equipped with a CNG fuelling station that allows us to refuel each bus at its parking space,” adds Vignol. In addition to the ten Scania CNG articulated buses, the metropolitan area around Angers Loire Métropole has also acquired a 12-metre Citywide, and other service vehicles now run on biogas. “I am happy about this progress and the ecological change,” explains Corinne Bouchoux, Vice President for Ecological Change and Transport.

Biogas plant in Nesselnbach expanded

CO2 liquefaction as an optimal complement

Regionalwerke AG Baden and Recycling Energie AG celebrated the official start of operations of the CO2 liquefaction plant in Nesselnbach AG with a ceremony and invited guests from politics and business. Hitachi Zosen Inova developed and delivered the turnkey project on behalf of the operating company CO2 Energie AG. It is a significant milestone on the way to decarbonising the Swiss energy system. The project is a best-practice example of optimised recycling management and maximised resource utilisation: carbon dioxide (CO2) previously released into the environment from the processing of biogas is now used in industrial applications, for example in processes in the pharmaceutical, medical or food industries. For this purpose, the biogas plant of Recycling Energie AG, which has already been feeding biogas into the grid since 2018, was supplemented by a CO2 liquefaction plant implemented by Hitachi Zosen Inova (pictured right). “The by-product CO2 becomes usable with the technically very complex plant expansion,” explains Philippe Lehmann, managing director of CO2 Energie AG. “From the gas processing plant it is fed into the liquefaction plant, where it is cleaned, filtered and dehydrated in several sub-steps. Cooling to minus 24 °C liquefies the CO2. This allows it to be compressed into tanks for storage and transport.” The plant in modular container construction with two scrubbing towers recycles the resulting carbon dioxide almost completely – up to 3000 tonnes per year.

CNG drive becomes more and more popular

Egypt to convert another 17’000 cars

The growth of Egypt’s gas production in recent years has encouraged the government to push ahead with the conversion to CNG as a fuel. Even CNG engines fuelled with natural gas emit up to 25 percent less CO2 than petrol and diesel engines. With biogas, one even drives almost CO2-neutral. The Egyptian Micro, Small and Medium Enterprises Development Authority (MSMEDA) has signed contracts worth around 6 million francs with Egyptian International Gas Technology (Gastec) and Cargas, a subsidiary of the Egyptian Ministry of Petroleum and Mineral Resources, to convert thousands of vehicles from petrol to CNG power. This will implement the ninth phase of an initiative to convert 150’000 vehicles to CNG operation, which was launched by the Ministry of Trade and Industry in early 2021. Bassel Rahmy, CEO of MSMEDA, said 61 CNG filling stations had also been built between July 2022 and the end of March 2023, bringing the total number in the country to 688. Another 221 stations are expected to be opened in the near future, with a total of 1000 refuelling facilities planned.

Sustainable refueling in France

CNG, LNG and electricity in one fell swoop

In the Ain department in the east of France, which incidentally also borders the Swiss cantons of Geneva and Vaud, the energy provider Proviridis inaugurates a Muti-Energie filling station in Viriat. After the opening of the CNG filling station in Narbonne (South of France), this is already the second opening ceremony within a short time. The filling station in Viriat is promoted by the regional initiative “GNVolont’Air”, a network of actors who want to accelerate the development of CNG and biogas in the Auvergne-Rhône-Alpes region. The main actors also include the company GRDF (Distribution de Gaz Naturel en France) and the Agency for Environment and Energy (ADEME). The new filling station is a real multi-energy hub for cars, trucks and buses, as it offers CNG and LNG, but also fast-charging stations for electric vehicles, and is open 24 hours a day, seven days a week. The CNG station is equipped with NGV1 and NGV2 connections, accepts all types of CNG-powered vehicles and offers a wide range of payment options.

LNG ferry ship christened in a ceremony

“Richmond” sets sail in a climate-neutral manner

The new LNG ferry vessel of Stadtwerke Konstanz GmbH, which will operate on the route between Konstanz/Staad and Meersburg from summer onwards, was ceremonially named “Richmond” on 17 June 2023. It is named after the twin town of Richmond upon Thames (UK) of the city of Constance. The 82.5-metre long LNG ferry is one of the first inland passenger vessels in Europe to be powered by high-speed pure gas engines – two 8-cylinder gas engines from Rolls-Royce Power Systems with 1014 hp/746 kW each. The “Richmond” can be operated in a climate-neutral manner by filling it with LBG/Bio-LNG, i.e. liquefied gas from renewable sources. It is almost identical in construction to the currently newest ferry ship “Lodi” and thus offers space for 64 passenger cars and 700 passengers. A Protestant and a Catholic priest blessed the new ferry ship with holy water at the christening. And the Lord Mayor of the city of Constance Uli Burchardt and the Head of Administration of the British city of Richmond Gareth Roberts handed over the golden ship’s bell to the FS Richmond.

More biogas for the Principality of Liechtenstein

Feasibility for biogas plant examined

Ten years ago, the first biogas plant at ARA Bendern in the Principality of Liechtenstein went online, producing biogas for a total of 6.9 GWh in 2021. Biogas is renewable and thus an important component of the Energy Strategy 2030 and the Energy Vision 2050 of the small state. The feasibility study commissioned by the Liechtenstein Energy Agency and the St. Gallen Energy Agency with the involvement of several project participants, including Liechtenstein Wärme, shows the possibilities and potential for a larger biogas plant in the Liechtenstein, Rhine Valley, Sargans-Werdenberg area. It concludes that both Schaan (FL) and Rüthi in SG would be suitable for the realisation of such a biogas plant. The investment sum is estimated at 30 to 40 million Swiss francs. A volume balance of biogenic waste (mainly green waste) from the region of approximately 30,000 tonnes per year was evaluated. With this raw material, about 13 GWh of biogas could be produced with the addition of other energy sources. This corresponds to about one percent of Liechtenstein’s energy demand. The potential site in Schaan proposed in the study would be a good location due to its central location in the catchment area and the easy use of CO2-neutral district heating to cover the heat demand. However, this is located in a groundwater protection area, so other potential sites should be examined.

Lean & Green award for Lidl Switzerland

First company in Switzerland to receive 3 stars

Lidl Switzerland significantly reduces its CO2 emissions and is the first company in Switzerland to receive the third star from Lean & Green (3rd Star). In Switzerland, the Lean & Green initiative is supported by GS1 Switzerland. Founded in Holland in 2008 and now established in over 16 countries, the campaign supports companies in transport and logistics in reducing their CO2 emissions. For the third star of Lean & Green, a reduction of 5 percent within two years would have been necessary. Lidl Switzerland was able to significantly exceed this target with a CO2 reduction of 11.77 percent. Since 2020, 1774 tons of CO2 have been saved in the logistics and transport area with the implementation of various measures. For this commitment, Lidl Switzerland is now the first company to be awarded the third star by Lean & Green. Ueli Rüger, Head of Logistics at Lidl Switzerland «This award confirms that we are on the right track. I am enormously proud of this great team achievement, but also of the courage and innovative strength of our logistics partners Krummen Kerzers AG, Thurtrans AG, Schöni Transport AG and KMT Transport, who have set out with us on the road to tomorrow. And spurs us on all the more to continue giving our full commitment to environmentally and climate-friendly logistics. We are sticking to our goal of supplying all our stores completely fossil-free by 2030 at the latest, thanks to our openness to technology.» This has been made possible by the use of alternative drive technologies and renewable fuels in logistics: as of today, more than 30 LNG trucks, four CNG trucks (powered by 100 percent Swiss biogas), and one electric truck are in use for Lidl Switzerland. Lidl Switzerland also operates two LNG filling stations, which are gradually being converted to fossil-free LBG/bio-LNG. Around 30 percent biodiesel is also blended into several diesel trucks. Schöni Transport AG, which is also continuously improving its transport and logistics processes, was also awarded its second star of the prestigious Lean & Green label. Schöni Transport AG relies on a holistic sustainability strategy that includes the use of vehicles with alternative drives (biodiesel, hydrogen fuel, LNG, and soon also electric), the optimization of routes and logistics processes (keyword «paperless dispatching»), and the promotion of a conscious use of resources.

Sustainability at one of the biggest sporting events

Winner of the hearts at the Giro d’Italia

The Slovenian professional cyclist Primoz Roglic won the Giro d’Italia and was able to put on the maglia rosa in Rome (I). The sprinter and former world champion Mark Cavendish won the mass sprint of the last Grio stage. However, the winner of hearts at the 106th edition, which ran from 6 to 28 May 2023 over 21 stages, around 3500 km and over 50,000 metres of altitude, was a pink Iveco S-Way with LNG propulsion. Together with two Iveco Daily models, the LNG-powered truck, which was supplied with liquefied biogas from Vulcangas, was at the head of the Carovana, the popular parade of decorated vehicles that drives ahead each race day, creating a festive atmosphere with music and entertainment until the professional cyclists pass the tens of thousands of spectators. Thanks to the collaboration with Vulcangas, the LNG Iveco was refuelled at the main service stations along the route, namely San Vitaliano, Forlì, Porcari, Turin and Agrate Brianza. With its autonomy of 1600 kilometres and an engine that guarantees excellent torque even on the narrowest of roads and difficult-to-access back roads, the Iveco S-Way once again proved to be the perfect transport and towing vehicle. “We are delighted to provide such a popular and vibrant event as the Giro d’Italia with the reliability and endurance of our vehicles, and we are even more proud to do so in a sustainable way,” explains Massimiliano Perri, General Manager Iveco Italy. “Thanks to an Iveco S-Way LNG powered by biogas, which not only leads the promotional caravan, but also paves the way for change in transport.”

New Holland: Sustainable and stylish

Design award for LNG tractor

New Holland Agriculture, a CNH Industrial brand, has won a Green Good Design Award for its prototype LNG-powered tractor, the T7 Methane Power LNG. These design awards are presented by the Chicago Athenaeum, the museum of architecture and design, and the European Centre for Architecture, Art, Design and Urban Studies. The new T7 prototype also underlines New Holland Agriculture’s pioneering role in the search for alternative fuel solutions. Its LNG propulsion system offers four times the fuel storage capacity of the T6 model, the world’s first commercialised CNG-powered tractor, more than doubling autonomy/range in the field. The LNG tractor also combines style, function and sustainability and features an all-new exterior with a redesigned bonnet and state-of-the-art lighting, which has now been recognised with the prestigious Green Good Design Award.