Portal for more climate-friendly mobility

Something big is growing

The fermenters currently growing in northern Germany are an impressive 25 metres high. As early as this autumn, Europe’s largest and most modern biogas plant will be producing plenty of green energy for the climate change.

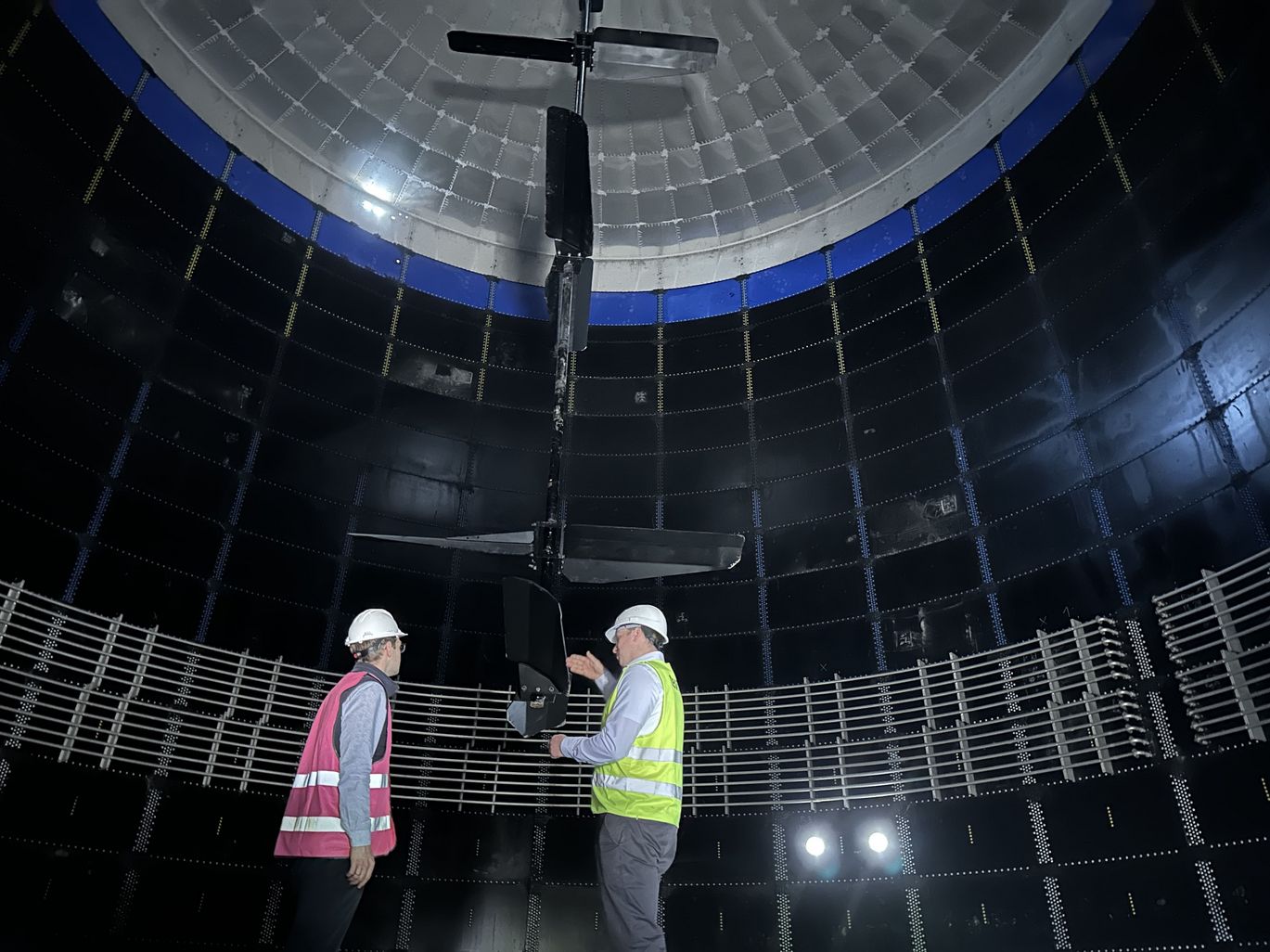

Project engineer Niklas Hense (right) explains details of the impressive biogas plant in northern Germany at the construction site. Source: Revis Bioenergy

Project engineer Niklas Hense (right) explains details of the impressive biogas plant in northern Germany at the construction site. Source: Revis Bioenergy

Construction is still underway directly on the North German coastal canal in the district of Cloppenburg, but the dimensions of the planned biogas plant – perhaps biogas plant is a more appropriate term given the dimensions – are already clear. On an area of 13.5 hectares, Revis Bioenergy GmbH is building a plant that will convert about one million tonnes of manure and slurry per year into green fuel in the form of bio-LNG and biogas.

Bis jetzt läuft beim Bau der riesigen Biogasanlage alles nach Plan. Quelle: Revis Bioenergy

Bis jetzt läuft beim Bau der riesigen Biogasanlage alles nach Plan. Quelle: Revis Bioenergy

This will be produced on a grand scale: 7400 Nm³/h of biogas and an annual feed-in of around 690 GWh are envisaged, as is the extraction of 105,000 tonnes of liquid CO₂ or 8000 tonnes of green ammonia (NH₃). This is made possible by a multitude of perfectly coordinated technologies. For example, a fully automated “feeding” of the plant with manure and slurry will take place via two cranes working in parallel. This will be combined with very efficient, imposing digester towers, which require an energy input of less than 55 kW on a volume of 10,000 m³. In addition, a purification technology called pressure swing adsorption will be combined with a screw compressor system for liquefying CO₂ for greater efficiency.

One of the many 25-metre-high fermenter silos on the site with the agitator to keep the biogenic residues moving. Source: Revis Bioenergy

One of the many 25-metre-high fermenter silos on the site with the agitator to keep the biogenic residues moving. Source: Revis Bioenergy

“The entire technical architecture of the plant relies on highly efficient processes. And so far everything is going according to plan during construction,” says a pleased Simon Detscher, whose company Revis Bioenergy GmbH planned the plant and is also responsible for construction as general contractor. The first part of the multi-million project can be put into operation in autumn. “After about six months, we will then reach the target output in 2024,” Jan-Hendrik Friedrichs, the managing director of Nordfuel GmbH, which will ultimately operate the biogas plant, is certain.

Impressive the various fermenter silos on the 13.5 hectare site and how quickly the construction of the plant is progressing. Source: Revis Bioenergy

Impressive the various fermenter silos on the 13.5 hectare site and how quickly the construction of the plant is progressing. Source: Revis Bioenergy

Exciting weeks await Niklas Hense, Master of Science in Bioengineering and co-responsible for the construction of the plant, until production starts. “At peak times, up to 100 experts from 30 specialised companies are working here. One wheel meshes with the other,” he explains. The dimensions and technical complexity are unparalleled. “The trucks with the biogenic residues drive over one of the incoming scales, and a digitalised process then determines where the unloading takes place,” Hense explains. This prevents unnecessary waiting times. The delivered residues are pumped into the fermenters sorted by type. Up to 1200 cubic metres can be processed per hour in this way.

The new plant recycles enormous amounts of farm manure (chicken, turkey and cattle manure, pig or even cattle slurry) into sustainable fuel and green energy. Source: Nordfuel

The new plant recycles enormous amounts of farm manure (chicken, turkey and cattle manure, pig or even cattle slurry) into sustainable fuel and green energy. Source: Nordfuel

“At the end of the whole process there is then a modern biogas purification plant, which ensures that the quality of our end products is right,” adds Hense. In order to optimally coordinate and control the process steps, about 50 kilometres of cable were laid across the entire site. Parallel to the construction of the huge plant, Jan-Hendrik Friedrichs, Managing Director of Nordfuel, is already putting together his team and the structures for smooth operation. Thirty employees are already on board, and by the end of the project there will be around 60.

At peak times, up to 100 experts from 30 specialist companies were involved in the construction of the biogas plant. Source: Revis Bioenergy

At peak times, up to 100 experts from 30 specialist companies were involved in the construction of the biogas plant. Source: Revis Bioenergy

Another clever feature is that a fleet of CNG or LNG-powered trucks will be used for transport. “They will be fuelled with the biogas that we produce here ourselves,” Friedrichs says happily, because a filling station is also being built on the Nordfuel site. So here, too, a material cycle is closed. A small drop of bitterness: “For licensing reasons, the filling station will only be usable by us and our partners.” (pd/jas, 29 August 2023)

Current drone image of the biogas plant. Source: Revis Bioenergy

Current drone image of the biogas plant. Source: Revis Bioenergy

You might also be interested in

Shell Starship on record hunt