Portal for more climate-friendly mobility

New reactor concept for methanation

Synthetic energy sources make renewable energy transportable and storable for long periods of time – methane is one of them. Researchers at Empa have now developed a new reactor concept for methanation that reduces energy loss during production.

The German biofuel pioneer Verbio already has an entire fleet of CNG-powered trucks with biogas in the tank. Source: Verbio

The German biofuel pioneer Verbio already has an entire fleet of CNG-powered trucks with biogas in the tank. Source: Verbio

Sustainable mobility requires the replacement of fossil fuels with renewable energy. One way of doing this is by means of biogas. This is because biogas from waste materials is renewable and CO2-neutral, since the same amount of CO2 would be produced if the biomass were simply left to decompose unused. So along with other sustainable energy sources and synthetic methane, biogas helps reduce CO2 emissions on a massive scale.

For this reason, the direct use of renewable electricity in electrically powered vehicles makes just as much sense as using renewable energy to produce low-carbon fuels such as hydrogen and methane. What is more, these e-fuels can be used in existing fleets or as sustainable fuels for long-haul and heavy-duty transport. In Dübendorf ZH, Empa is working with partners in research, business and the public sector to investigate how future mobility might work without the use of fossil fuels.

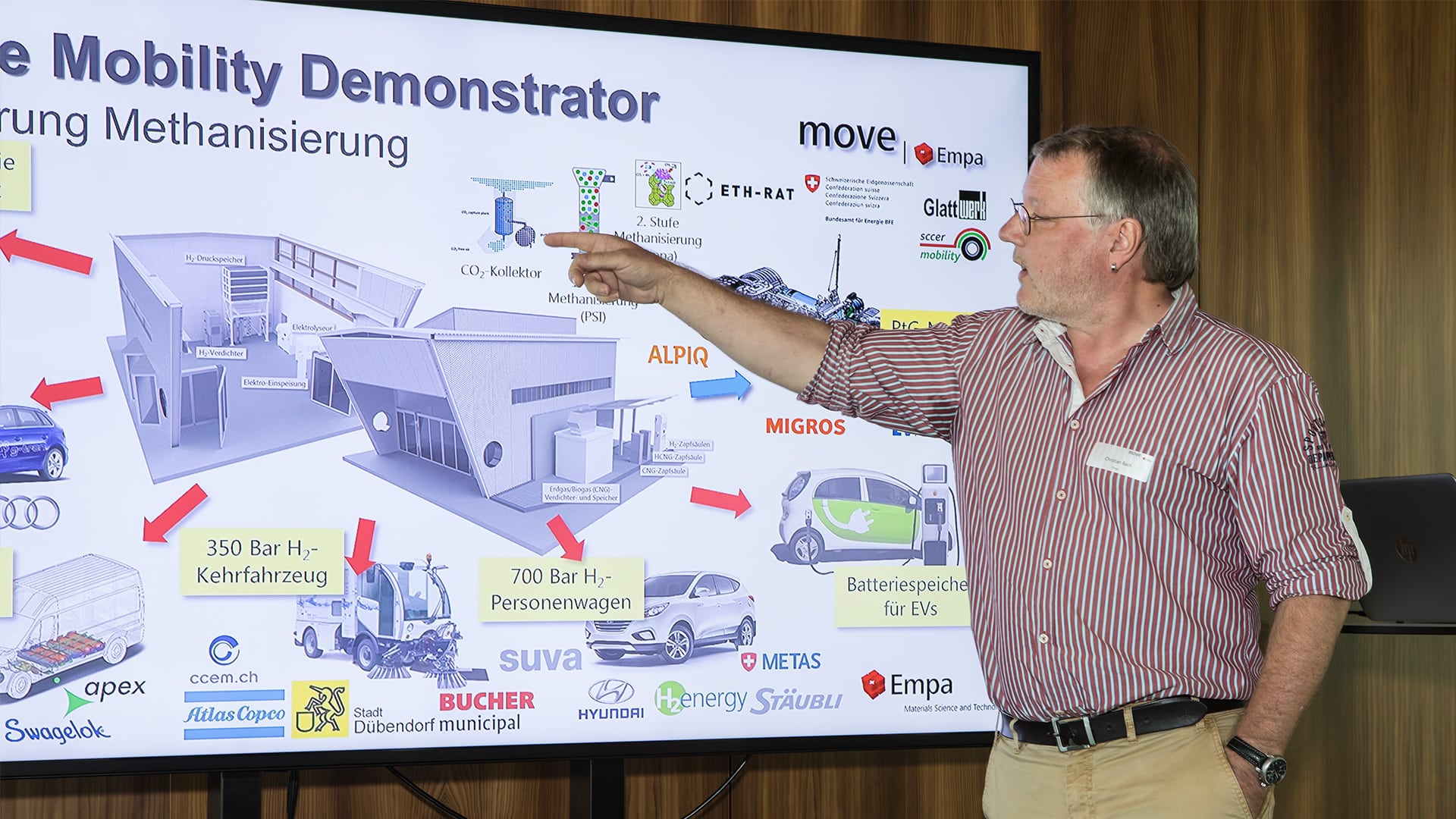

Christian Bach, Head of Empa’s Vehicle Propulsion Systems Department, explains how the mobility demonstrator “move” works. Source: Empa

Christian Bach, Head of Empa’s Vehicle Propulsion Systems Department, explains how the mobility demonstrator “move” works. Source: Empa

“Synthetic gas offers enormous potential if it is produced from atmospheric CO2 and hydrogen generated from renewable sources,” explains Christian Bach, Head of Empa’s Vehicle Drive Systems Department. “But in addition to renewable electricity, hydrogen production requires a lot of water. So with our mobility demonstrator, we’re looking to extract not just the CO2 but also the water for hydrogen production directly from the atmosphere using a CO2 collector developed by the ETH spin-off Climeworks.”

The mobility demonstrator known as “move” shows how passenger cars and lorries can already run on synthetic methane, but one problem that arises in producing the latter is the relatively high energy loss during conversion; what is more, existing processes require the methane to be purified. Empa researchers have now developed a new, optimised reactor concept for methanisation – i.e. the production of synthetic methane from hydrogen and CO2 – that reduces energy loss on a massive scale. The findings from the new reactor concept will also serve as a basis for the construction of new large-scale plants.

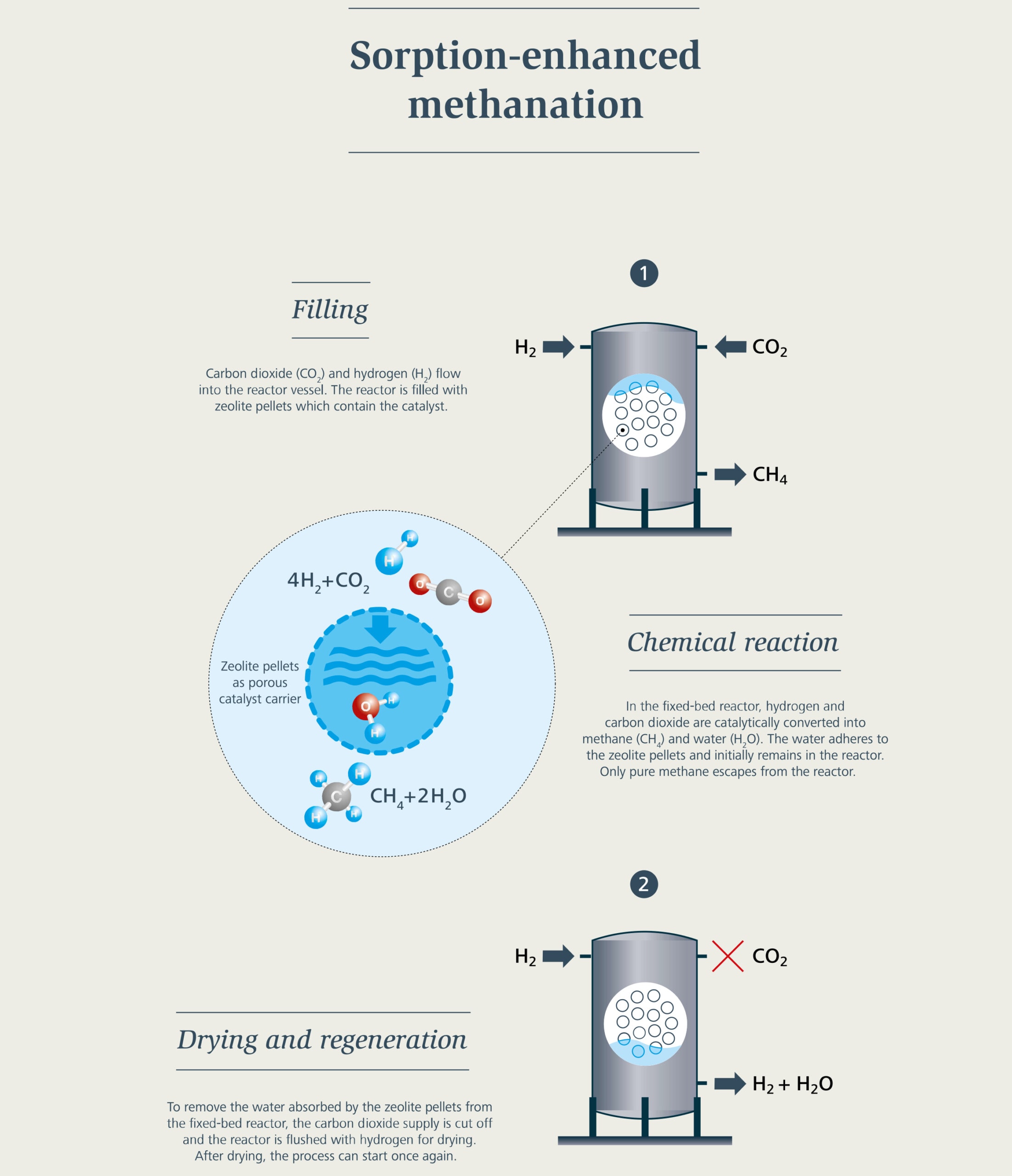

Source: Empa

Source: Empa

The gas produced by means of a catalytic process of this nature still contains hydrogen, so it cannot be fed directly into the gas grid Empa researchers Florian Kiefer, Marin Nikolic, Andreas Borgschulte and Panayotis Dimopoulos Eggenschwiler have now developed a new concept that prevents the formation of hydrogen on the product side. This results in easier process control and better suitability for dynamic operation, e.g. for coupling with volatile renewable energies. The hydrogen-free methane for “move” is produced by means of a process known as sorption-enhanced methanisation. The idea behind this is that the water generated during the reaction is continuously absorbed on a porous catalyst support during the methanation process. This continuous removal of water means that methane is the sole product – in its purest form. This eliminates the need to purify the product mixture, as was previously required prior to feeding the synthetic gas into the grid.

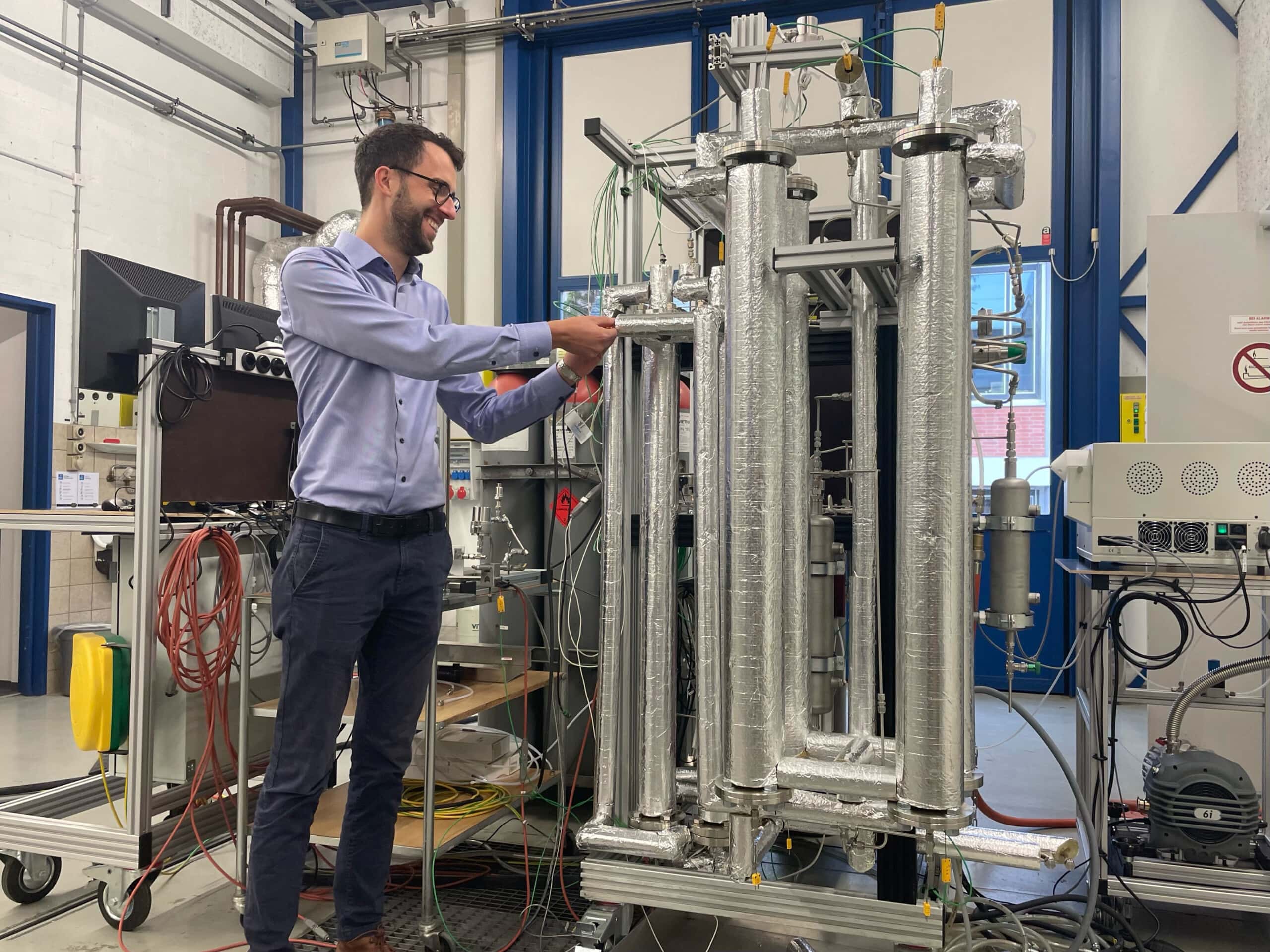

Empa researcher Florian Kiefer, project manager for sorption-enhanced methanation, checks the experimental plant. Source Empa

Empa researcher Florian Kiefer, project manager for sorption-enhanced methanation, checks the experimental plant. Source Empa

What is particularly ingenious about the concept is that at the end of the reaction process, the catalyst support material is dried by lowering the pressure – so it is ready for the next reaction cycle. “This process is more flexible and stable than previous methods,” explains Florian Kiefer, project manager for sorption-enhanced methanation. “It also has some energy-saving potential since we can run it at a lower reactor pressure and do without hydrogen separation and recirculation. Nonetheless, a precise assessment of the energy efficiency won’t be possible until the demonstrator has been completed.”

Florian Kiefer and his team spent around three years carrying out research into the new reactor concept. As the focus was also on upscaling the process, i.e. making it suitable for subsequent use in large-scale plants, the regeneration time for drying the reactor was particularly important. The solution: in order to ensure continuous methane production, at least two reactors must operate alternately. The new method will enable synfuels to be manufactured with less energy loss in the future – a crucial step towards eliminating this oft-repeated criticism of synthetic fuels. (pd/jas, 26 January 2023)

With their work, the Empa researchers show that synthetic energy carriers are not only cycle-friendly with regard to CO2, but can also make renewable energy transportable and storable in the long term. Source: Empa

With their work, the Empa researchers show that synthetic energy carriers are not only cycle-friendly with regard to CO2, but can also make renewable energy transportable and storable in the long term. Source: Empa

You might also be interested in

Shell Starship on record hunt