Portal for more climate-friendly mobility

“Mampf” takes circular economy further

Waste oil and biogenic waste from the college canteen “Mampf” at St. Gallen vocational training centre are turned into biodiesel and biogas: the circular economy model operated in cooperation with Bitrol is a smart contribution to reducing CO2. And it even helps control red mites in agriculture.

First avoid, then optimally recycle instead of wasting, this philosophy regarding food waste and resource wastage is already being implemented by the school restaurant “Mampf”. Source: Daniel Ammann/GBS St. Gallen

First avoid, then optimally recycle instead of wasting, this philosophy regarding food waste and resource wastage is already being implemented by the school restaurant “Mampf”. Source: Daniel Ammann/GBS St. Gallen

Food waste and the waste of resources in general are rightly a major headache at St. Gallen vocational training centre. That’s why the college restaurant “Mampf” is faced with a tricky task, especially during winter sports week: how many guests is the kitchen team to expect if students might alternatively sign up for a day in Savognin GR? Around 400 meals are usually consumed at lunchtime – including everything from set meals and sandwiches to salads and croissants. “Over the years, our range of food has grown and now covers a wide spectrum of products,” explains Thomas Riedener, head of “Mampf.”

In order to avoid food waste, Riedener and his team operate a system of pre-sign-ups and a “free-choice buffet” during sports week. Those who stay on site can freely put together their menu from a variety of cooked components. “This allows us to offer different variations of freshly prepared food over several days, as well as seeing how newly developed menus are received.” But even during regular operation, Riedener plans menus a few days in advance in order to avoid leftovers. This means that on Mondays, for example, you can enjoy Valais raclette with potatoes, and on Tuesdays Zurich-style sliced meat with typical Swiss rösti. Or Ghackets with macaroni one day and Köttbullar beef balls with mashed potatoes the next.

Thomas Riedener, manager of the “Mampf”, has been working successfully with Bitrol GmbH from Tübach SG for years. Source: Daniel Ammann/GBS St. Gallen

Thomas Riedener, manager of the “Mampf”, has been working successfully with Bitrol GmbH from Tübach SG for years. Source: Daniel Ammann/GBS St. Gallen

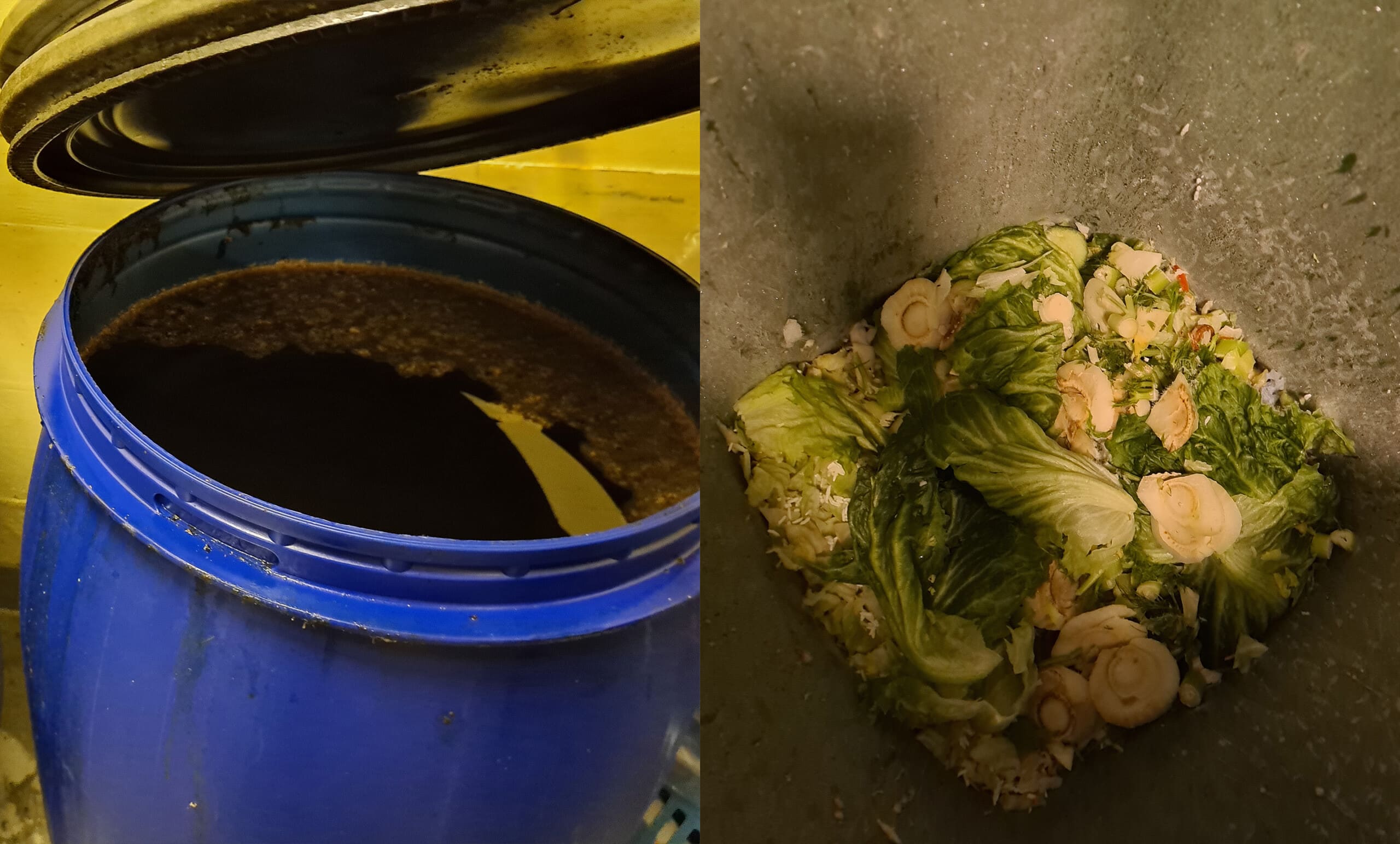

When preparing the food, too, the aim is keep emissions as low as possible. Breaded schnitzels are not fried in the pan but in the hot-air steamer, and chicken breast is first drizzled with a little fat and before likewise being prepared in the steamer. “We use a probe to make sure the chicken doesn’t dry out. This method means we don’t throw away any oil except what we need for the deep fryer.” The waste oil is collected in two 120-litre barrels and picked up every two to three months by Bitrol GmbH from Tübach (SG), along with the deep-frozen green waste – the St. Gallen company uses the same principle as the clever household waste container by Freezyboy. Freezing improves hygiene while also preventing decomposition, stench and fruit fly infestation – and ultimately even generates more energy because the biogas is not produced until the waste gets to the production plant.

Waste oil and biogenic residues are not simply disposed of by the school restaurant “Mampf”, but are specifically put to further use in order to close material cycles and save CO2. Source: GBS St. Gallen

Waste oil and biogenic residues are not simply disposed of by the school restaurant “Mampf”, but are specifically put to further use in order to close material cycles and save CO2. Source: GBS St. Gallen

“Mampf” chef Thomas Riedener and Bitrol CEO Patrick Bötschi are proud to have been collaborating on the project for more than ten years now. “We source used oil from a total of 150 restaurants in the area and have it processed into biodiesel,” explains Bötschi. During this manufacturing process, a quantity of glycerol is also produced: this is required as an element of Bitrol’s main product, namely Glypolsan. The latter is an effective remedy against the red mite – one of the most common parasites to be found in chicken coops.

In addition to mite control agent and biodiesel, the Trübach-based company also uses its biogas plant in Schwellbrunn AR to produce biogas from the residual breadcrumbs at the bottom of the waste oil barrels and the frozen, biogenic residue collected from “Mampf”, thereby closing the material cycle. “Everything is a valuable material – nothing is waste. We endeavour not to throw anything away,” says Patrick Bötschi. Thomas Riedener agrees: “We’re also constantly looking to optimise our work processes at “Mampf” so as to operate on an ecologically compatible yet cost-effective basis. There’s a growing awareness of this type of sustainable process among our guests, too.” Rather than return leftovers, vocational students, teachers and external guests prefer to ask for a second helping. In doing so, they all contribute to a successful circular economy, moving Switzerland one step closer to achieving the net zero target. (mig/jas, 26. Januar 2023)

Vocational school students, teachers and external guests also make their contribution to combating the waste of resources at the GBS in St. Gallen. Source: Daniel Ammann/GBS St. Gallen

Vocational school students, teachers and external guests also make their contribution to combating the waste of resources at the GBS in St. Gallen. Source: Daniel Ammann/GBS St. Gallen

You might also be interested in

Shell Starship on record hunt